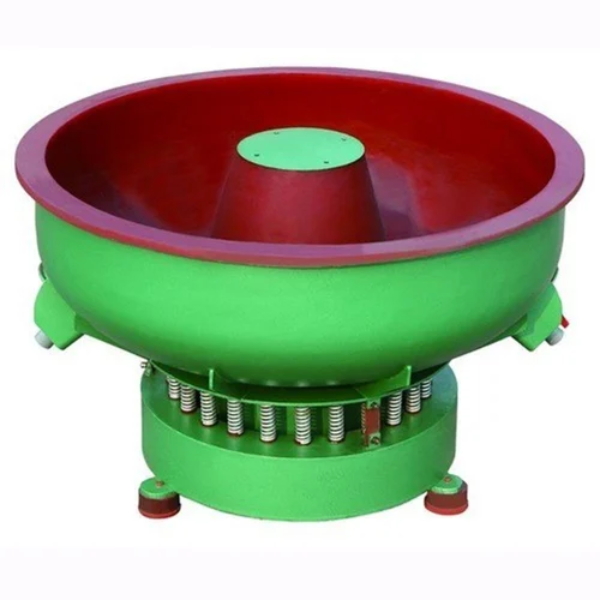

Finishing metal components manually can be slow and inconsistent. A vibratory deburring machine helps solve this by smoothing edges and removing burrs in a controlled, repeatable manner. At Separation Engineers in Navi Mumbai, the machine is designed to deliver cleaner, safer, and more uniform components.

Parts move with abrasive media inside a vibratory chamber, allowing all edges to be treated evenly. This improves assembly quality and reduces the risk of sharp surfaces causing issues later. For industries that handle high part volumes, the time savings are significant.

Depending only on manual deburring often leads to delays and unpredictable results. A vibratory system helps avoid these problems and builds consistency into your finishing process.

Reach out to us for guidance on selecting the right deburring setup for your parts.